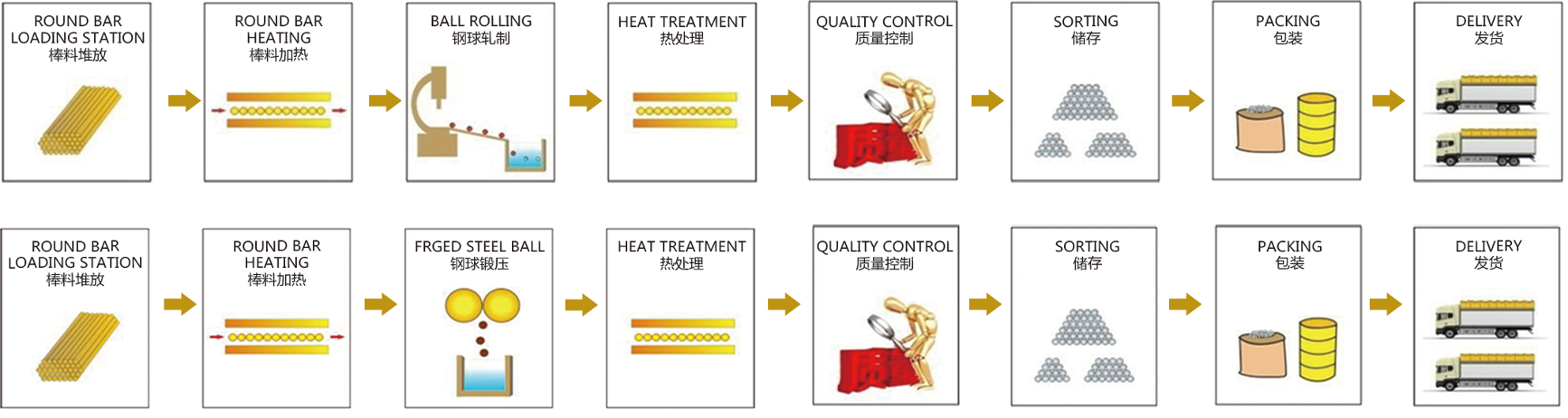

Forged Steel Ball Technological Process

1. The raw material used for forged ball mill steel balls is hot-rolled low-alloy round steel bars.

2. Before forging, the raw materials are heated to an appropriate temperature in a walking-beam heating furnace.

3. The hot raw materials are sent into a set of forging equipment and are continuously forged into steel balls through several forging processes under the hot state.

4. The red-hot forged steel balls immediately enter the specially designed heat treatment production line of the company for heat treatment to obtain a very high and uniform hardness of the steel balls.

5. The finished steel balls have precise dimensions and geometric shapes, as well as good wear resistance and mechanical properties.

6. The qualified products are sent to the finished product warehouse, packaged and then delivered to customers.

Rolling Steel Ball Technological Process

1. The raw material used for rolled ball mill steel balls is hot-rolled round steel bars, whose diameter is approximately the same as the nominal diameter of the steel balls.

2. Before rolling, the raw materials are heated to an appropriate temperature in a medium-frequency heating furnace or a walking-beam heating furnace.

3. When the red-hot raw materials are sent into the steel ball rolling mill, they rotate and advance between two rollers with special spiral pass shapes and are continuously rolled into steel balls. Different specifications of rolling mills can roll 40 - 260 steel balls per minute.

4. The red-hot rolled steel balls immediately enter the specially designed heat treatment production line of the company for heat treatment to obtain a very high and uniform hardness of the steel balls.

5. The finished steel balls have precise dimensions and geometric shapes, as well as good wear resistance and mechanical properties.

6. The qualified products after inspection are sent to the finished product warehouse, packaged and then delivered to customers.